Induction Hardening Steel Cam

Views Send Enquiry

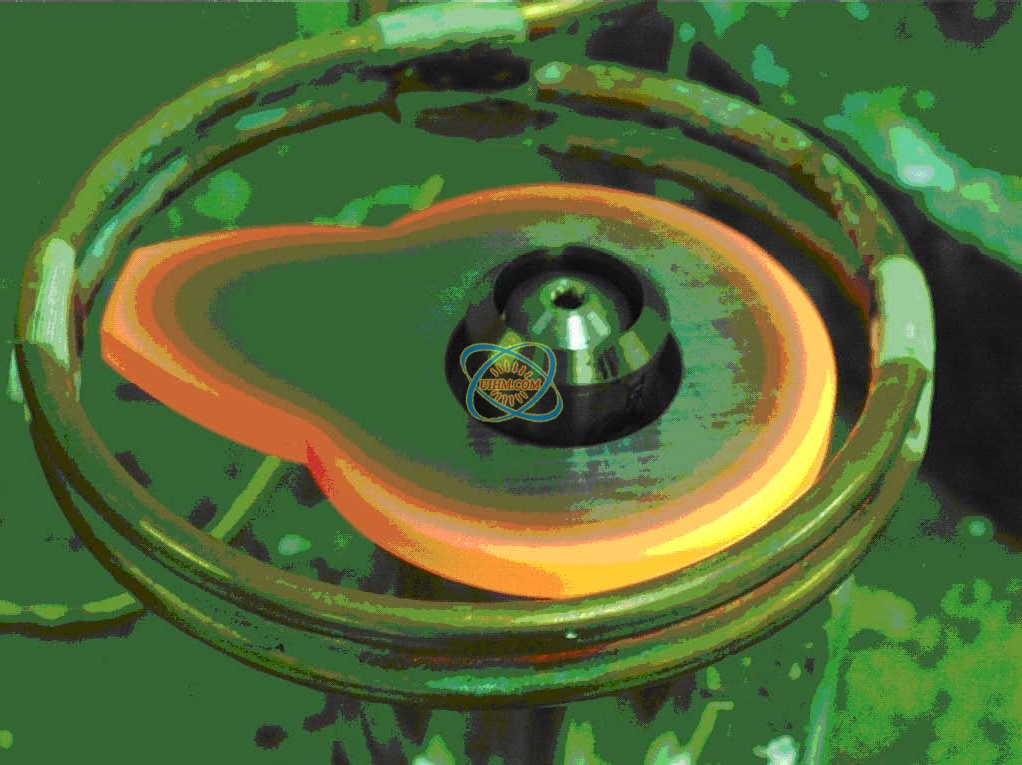

Objective To harden the perimeter of ¼” thick steel cam assemblies

Material ¼” thick steel cam assemblies of varying geometries

Temperature 1650 ºF (900 °C)

Frequency 177 kHz

Equipment Power of 20 kW, induction heating system, equipped with a remote heat station containing one 1.0μF capacitor and an induction heating coil designed and developed specifically for this application

Process A two-turn helical coil is used to heat the cams. The heat time varies from 120-150 seconds. After heating, the parts are quenched in water.

Results/Benefits Hardening the cam outer surfaces with induction results in:

• uniform heating for uniform results

• one coil can be used for many geometries

• consistent results from piece to piece

Related Content

Air Cooled clamp coil (half-open coil) for preheating gas pipeline

induction coating by air cooled clamp induction coil

Remove plastic coating from steel tubes by Induction Heating

Releasing Fixture by Induction Heating

U shape air cooled induction coil by UM-100C-HF for pipeline preheating

induction quenching with custom-design inductor

induction brazing diamond segment

induction brass soldering copper plate_2

Hot

induction hardening axle (shaft) by 100KW induction heater

induction quenching axle (shaft) by 160KW induction heater

induction hardening inner surface (inwall)

Induction Hardening Harvestor Combined Finger

Induction Hardening Harvestor Combined Blade

workpiece for induction hardening

induction hardening veterinary instrument

induction hardening surgical device

Newest Comment

No Comment

Post Comment