Induction Heating Titanium Blade

Views Send Enquiry

Heating Titanium Blade

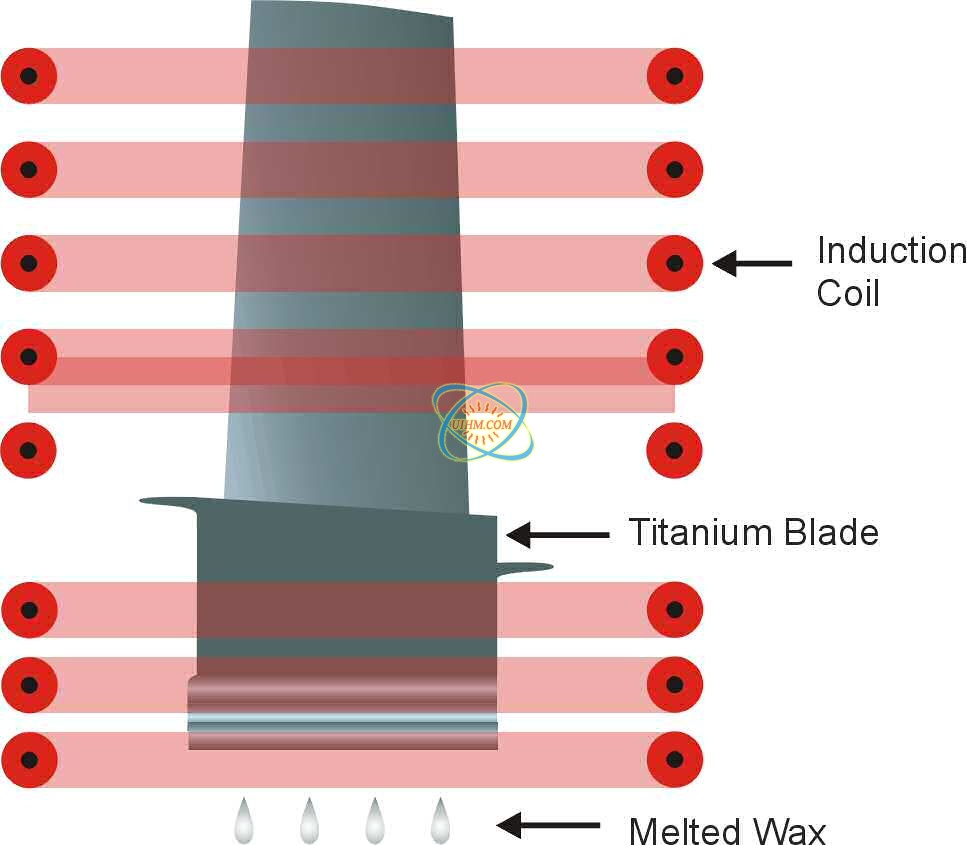

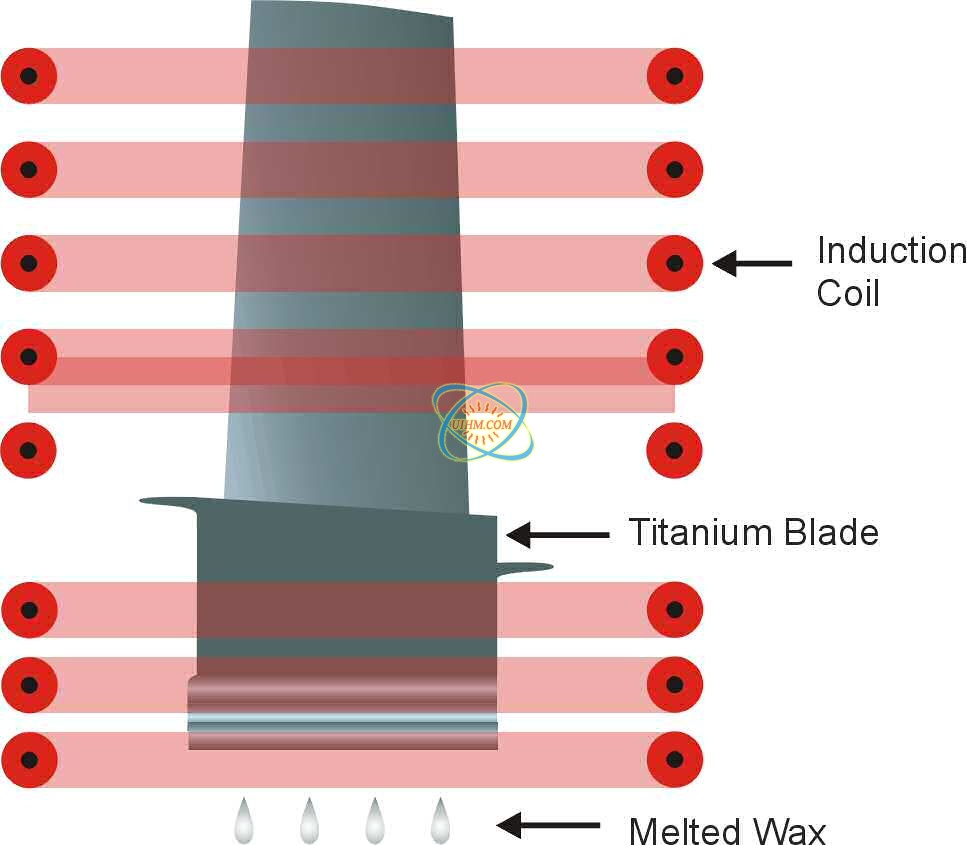

Objective Heat a titanium blade to 500°F (200°C) to melt and drain the wax from inside the blade.

Material 4” length (101.6mm) titanium blades with 1.5” x 0.25” (38.1mm x 6.4mm) metering area

Temperature 500°F (200°C)

Frequency 186 kHz

Equipment • Power of 10kW induction heating system equipped with a remote workhead.

• An induction heating coil designed and developed specifically for this application.

Process A specially designed eight-turn helical coil is used to heat to the blades. Power is applied for 3.5 minutes. The wax melts and drips out of the blade.

Results/Benefits Induction heating provides:

• Uniform and repeatable performance

• Faster application time

• Non-contact heating

Heating Titanium Blade

Good

Bad

Related Content

Air Cooled clamp coil (half-open coil) for preheating gas pipeline

induction coating by air cooled clamp induction coil

Remove plastic coating from steel tubes by Induction Heating

Releasing Fixture by Induction Heating

U shape air cooled induction coil by UM-100C-HF for pipeline preheating

induction quenching with custom-design inductor

induction brazing diamond segment

induction brass soldering copper plate_2

Hot

induction heating bolt

induction heating steel rod by UM-40AB-HF

induction heating end of pipeline by 160kw induction heater

induction heating steel plates by auto feed system with 120KW induction heater

induction heating cambered work-piece by 160KW power supply

Induction heating for Plastic Reflow With Catheter Tubing

U shape induction coil for heating hole

induction heating steel rod with double coils

Newest Comment

No Comment

Post Comment