Induction Hot Forming Titanium Rod

Views Send Enquiry

Objective To heat a titanium rod to 1700°F (926.7°C) within 60 seconds for hot forming.

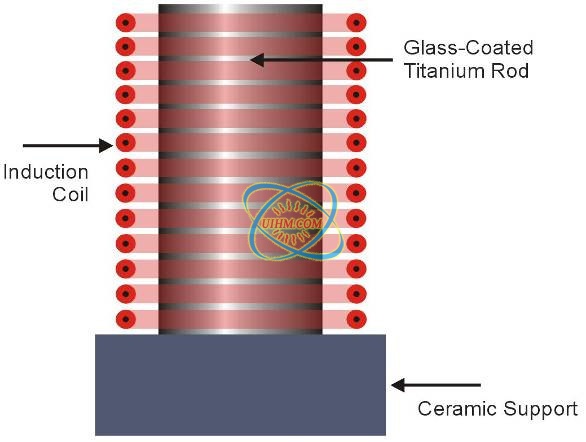

Material Titanium rods, 1.25”(31.8mm) diameter, 5”(127mm) length

Temperature 1700°F (926.7°C)

Frequency 70 kHz

Equipment • Power of 60kW induction heating system, equipped with a remote workhead.

• An induction heating coil designed and developed specifically for this application.

Process A specially designed thirteen-turn helical induction coil is used to heat the titanium rod to 1700ºF (926.7°C). Two optical pyrometers are used to measure the temperature at the surface and center of the part. Both the surface and center of the titanium rod are heated to 1700ºF (926.7°C) within 60 seconds.

Results/Benefits Induction heating provides:

• Improved production rates with minimal defects

• Improved mechanical properties

• Even distribution of heating

Related Content

Air Cooled clamp coil (half-open coil) for preheating gas pipeline

induction coating by air cooled clamp induction coil

Remove plastic coating from steel tubes by Induction Heating

Releasing Fixture by Induction Heating

U shape air cooled induction coil by UM-100C-HF for pipeline preheating

induction quenching with custom-design inductor

induction brazing diamond segment

induction brass soldering copper plate_2

Hot

induction heating bolt

induction heating steel rod by UM-40AB-HF

induction heating end of pipeline by 160kw induction heater

induction heating steel plates by auto feed system with 120KW induction heater

induction heating cambered work-piece by 160KW power supply

Induction heating for Plastic Reflow With Catheter Tubing

U shape induction coil for heating hole

induction heating steel rod with double coils

Newest Comment

No Comment

Post Comment