Induction Soldering Radio Antenna

Views Send Enquiry

Objective To heat a coaxial antenna assembly to 600°F within 2 seconds for a soldering application. The goal to improve on an existing procedure with a soldering iron which required 10 to 15 seconds.

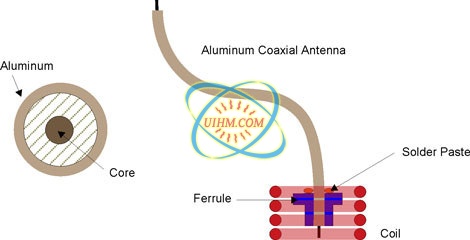

Material .250” diameter aluminum antenna assembly, aluminum ferrule, solder paste, temperature indicating paint

Temperature 600°F

Frequency 333 kHz

Equipment Power of 6 kW power supply, remote heat station with one 1.2 μF capacitor and a specially designed induction coil.

Process Initial tests were conducted with temperature indicating paint to establish a heating profile and determine time-to-temperature. The solder paste was then applied to the antenna assembly and aluminum ferrule. RF power was applied for two seconds to heat and flow the solder joint.

Results Consistent and repeatable results were achieved within the required two-second time frame. A close examination of the solder joint indicated that the solder flowed well and formed a good, solid joint.

Soldering Radio Antenna

Related Content

Air Cooled clamp coil (half-open coil) for preheating gas pipeline

induction coating by air cooled clamp induction coil

Remove plastic coating from steel tubes by Induction Heating

Releasing Fixture by Induction Heating

U shape air cooled induction coil by UM-100C-HF for pipeline preheating

induction quenching with custom-design inductor

induction brazing diamond segment

induction brass soldering copper plate_2

Newest Comment

No Comment

Post Comment