Induction Heating fan blades for welding

Views Send Enquiry

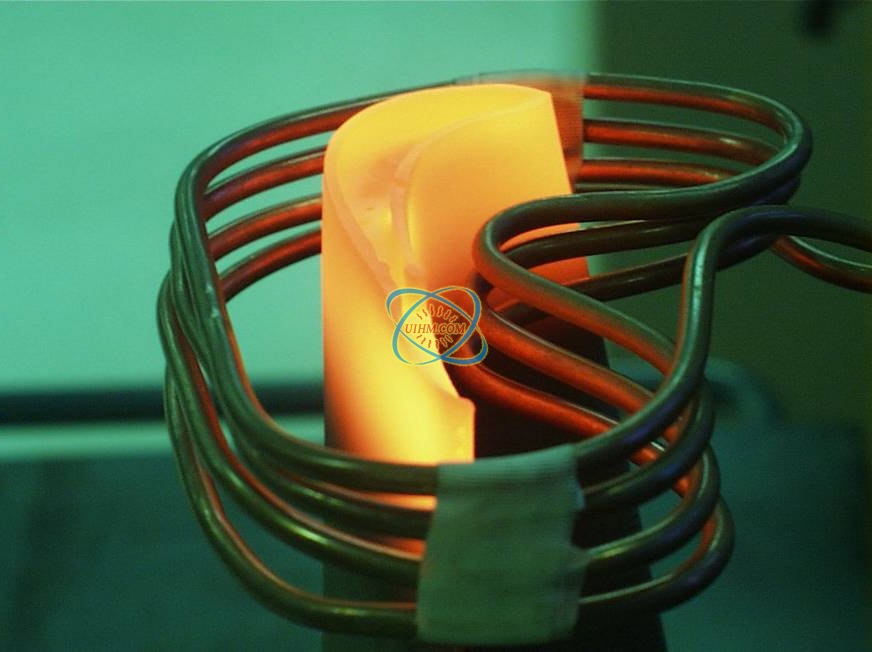

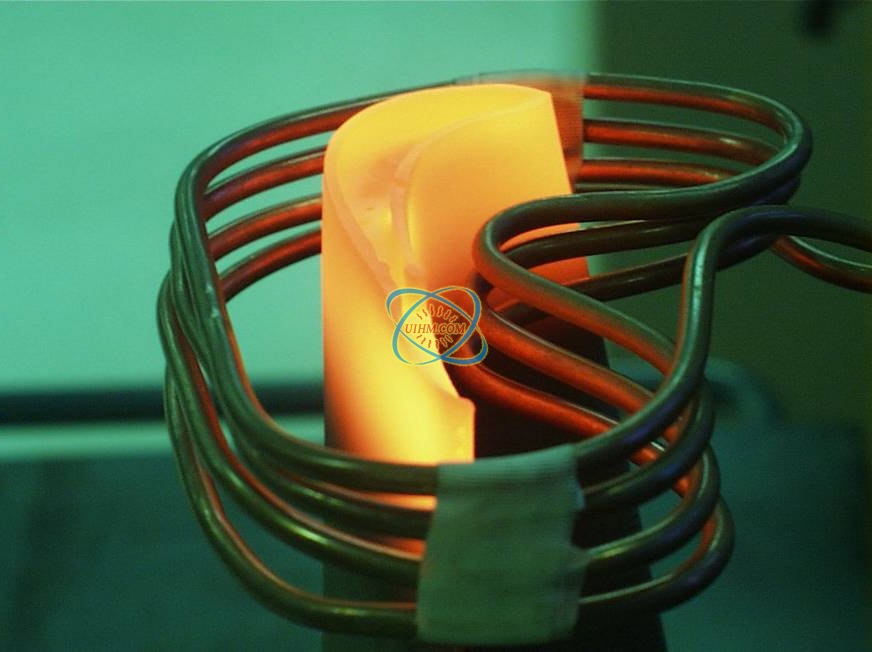

Objective To uniformly heat jet engine turbine fan blades to 1800°F (982.2ºC) within five minutes for a welding application

Material Jet engine turbine fan blades with 2”(50.8mm) length tip

Temperature 1800°F (982.2ºC)

Frequency 216 kHz

Equipment • Power of 6kW induction heating system equipped with a remote workhead.

• An induction heating coil designed and developed specifically for this application.

Process A four-turn helical coil with a kidney shape is used to provide uniform heat for this application. The turbine blade is placed inside the coil and power is applied for 5 minutes until the top

0.25” (6.35mm) of the blade reaches 1800°F (982.2ºC). An optical pyrometer is used to measure the temperature of the

part.

Results/Benefits Induction heating provides:

• Even and consistent distribution of heat

• Faster production rate

• Reduces product waste through rapid heat-up and cool down cycles

Heating fan blades for welding

Related Content

Air Cooled clamp coil (half-open coil) for preheating gas pipeline

induction coating by air cooled clamp induction coil

Remove plastic coating from steel tubes by Induction Heating

Releasing Fixture by Induction Heating

U shape air cooled induction coil by UM-100C-HF for pipeline preheating

induction quenching with custom-design inductor

induction brazing diamond segment

induction brass soldering copper plate_2

Hot

induction welding automotive stainless plate for Toyato

induction welding drill bit (bore bit or drill pipe or drill rod or cutting pick)

induction welding steel bar

induction welding motor short-curcuit ring by flexible handle induction coil

induction welding motor (generator windings) short-curcuit ring

induction welding phosphor copper rings

induction tin soldering distributor branches

induction Welding for stainless stell workpiece

Newest Comment

No Comment

Post Comment