Induction Heat braided cable

Views Send Enquiry

Objective Prior to cutting, heat a short section of a hardened steel cable coated with a polyethylene sheathing.

Material Multi-strand braided stainless steel cable 0.5 in. (1.27 cm) OD enclosed within a polyethylene sheathing

Temperature 1800 ºF (982) ºC

Frequency 40 kHz

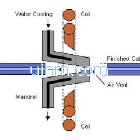

Equipment • Power of 60kW induction heating system, equipped with a remote workhead containing four (4) 1.0 μF capacitors (for a total of 1.0 μF).

• An induction heating coil designed and developed specifically for this application.

Process A three-turn helical coil is used to heat the cable in approximately 2 seconds. After the power is turned off, the

heat is then transferred to the sheathing.

Results/Benefits Induction heating provides a quick, precise repeatable method

to reach the high temperature required. It is a very efficient heating method.

Heat a braided cable

Related Content

Air Cooled clamp coil (half-open coil) for preheating gas pipeline

induction coating by air cooled clamp induction coil

Remove plastic coating from steel tubes by Induction Heating

Releasing Fixture by Induction Heating

U shape air cooled induction coil by UM-100C-HF for pipeline preheating

induction quenching with custom-design inductor

induction brazing diamond segment

induction brass soldering copper plate_2

Hot

induction heating bolts from turbine

induction debonding from steel rod

induction debonding rubber

Releasing Fixture by Induction Heating

Remove plastic coating from steel tubes by Induction Heating

Induction Heating catheter tipping die

Induction Molding for teflon catheter tip

induction melting for crystal growth

Newest Comment

No Comment

Post Comment