Induction Bonding Rubber to Steel

Views Send Enquiry

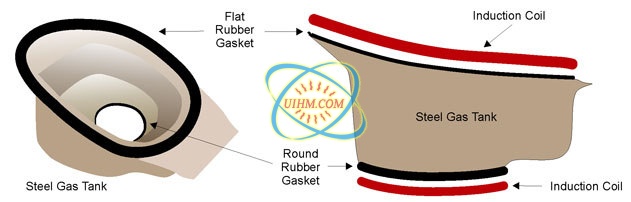

Objective To bond rubber gaskets to the top and bottom of a steel gas tank assembly.

Material Flat and round rubber gaskets, steel gas tank assembly

Temperature 300 to 350°F(148.9-176.7°C)

Frequency 183 kHz for the flat gasket; 231 kHz for the round gasket

Equipment •Power of 15kW induction heating system equipped with a remote workhead containing two 1.25 μF capacitors for a total of 0.625 μF

• An induction heating coil designed and developed specifically for this application.

Process Two two-turn pancake coils are specially contoured to the the shape of the steel assembly to produce uniform heat in the gasket areas. The gaskets are positioned over the joint areas.

Power is applied for 6.5 seconds to reach the bonding temperature of 320°F (160°C).

Results/Benefits Induction heating provides:

• Repeatable, rapid & accurate heating cycles

• Reduced process time

• Even distribution of heat

Related Content

induction brazing SS steel by handheld induction coil

induction melting silicon and steel

magnesium oxide acidic furnace for induction melting glass

induction preheating gas pipeline by full air cooled clamp induction coil and DSP induction heater

induction melting with Titanium alloy pot by customized induction coil

induction melting aluminium for casting wire wheel

induction heating steel plate by pancake induction coil

induction heating steel knife

Hot

induction painting after induction bending for pipelines

induction heating steel plate

induction remove copper from aluminium

induction heating stator frame

induction heating graphite mould

difference between induction heating inner surface and outside surface of steel ring

induction heating steel pot bottom

induction heating for heat preservation

Newest Comment

No Comment

Post Comment