Induction Heating Aluminum Auto Trim

Views Send Enquiry

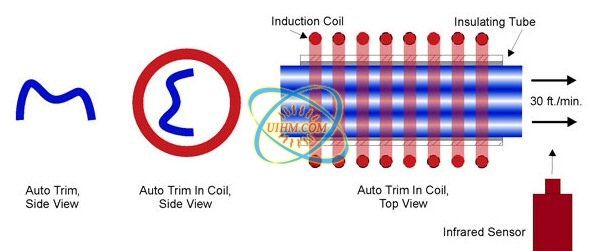

Objective :To heat various sizes of aluminum auto trim to 500°F (260°C) at a rate of 30 ft. (9.1m) per minute for curing an adhesive.

Material: Magnetic steel and aluminum auto trim parts, coated with adhesive; 1.85” (47mm) ID ceramic tube

Temperature :500 °F (260°C)

Frequency :152 kHz

Equipment

• HF 25kW induction heating system equipped with a remote workhead with six 0.75μF capacitors for a total capacitance of 0.5 μF

• An induction heating coil designed and developed

specifically for this application.

Process :To simulate continuous production, a slide table/stepping motor arrangement and ceramic tube are used to move the parts through the eight turn helical coil at 30 ft. (9.1m) per minute. In continuous production, an infrared sensor can be used to measure the temperature of the aluminum after exiting the coil and adjust output of the power supply to maintain the required 500 °F (260°C).

Results/Benefits:

• Consistent, controllable heat

• Hands free operation

• Reliable, repeatable results

Related Content

induction brazing SS steel by handheld induction coil

induction melting silicon and steel

magnesium oxide acidic furnace for induction melting glass

induction preheating gas pipeline by full air cooled clamp induction coil and DSP induction heater

induction melting with Titanium alloy pot by customized induction coil

induction melting aluminium for casting wire wheel

induction heating steel plate by pancake induction coil

induction heating steel knife

Hot

induction painting after induction bending for pipelines

induction heating steel plate

induction remove copper from aluminium

induction heating stator frame

induction heating graphite mould

difference between induction heating inner surface and outside surface of steel ring

induction heating steel pot bottom

induction heating for heat preservation

Newest Comment

No Comment

Post Comment