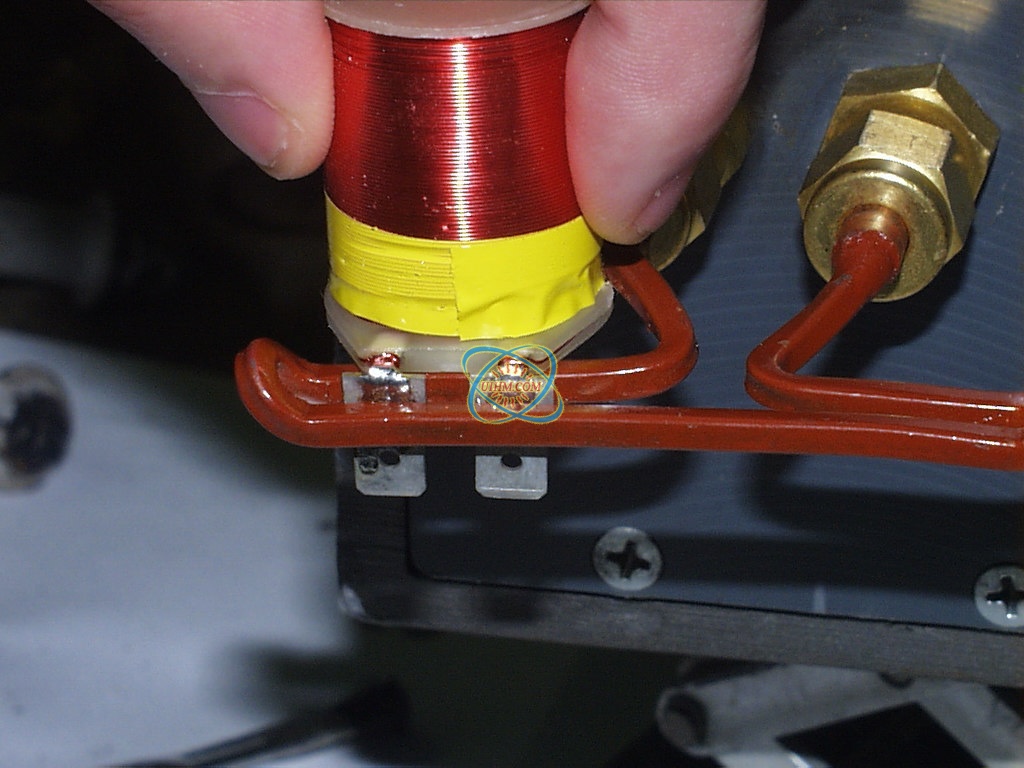

Induction Soldering wires onto connector

Views Send Enquiry

Objective Heat connector assemblies for soldering

Material Device assembly

Tin plated brass terminals Solder paste

Temperature 500°F (260°C) 5-7 seconds

Frequency 360 kHz

Equipment Power of 6 kW induction heating system equipped with a remote heat station, containing two 0.66 μF capacitor.

An induction heating coil designed and developed specifically for this application.

Process A single turn helical coil is used to heat the solder paste. The

connectors are placed inside the induction heating coil and RF power is applied for 5-7 seconds until the connector heats.

Solder paste is applied to the joint in two ways, stick-fed or manually.

Results/Benefits • Compared to using a manual soldering iron, induction

heating precisely applies heat to for higher quality solder joints

• This is ideal for integrating with an automated system. By stick- feeding the solder more aesthetically pleasing parts are produced.

Soldering wires onto connector

Related Content

induction brazing SS steel by handheld induction coil

induction melting silicon and steel

magnesium oxide acidic furnace for induction melting glass

induction preheating gas pipeline by full air cooled clamp induction coil and DSP induction heater

induction melting with Titanium alloy pot by customized induction coil

induction melting aluminium for casting wire wheel

induction heating steel plate by pancake induction coil

induction heating steel knife

Newest Comment

No Comment

Post Comment