Induction bonding Metal to plastic

Views Send Enquiry

Objective: Bond an aluminium mesh to a plastic beer keg

Objective: Bond an aluminium mesh to a plastic beer kegMaterial : Aluminium mesh

. Plastic keg 320 mm (12.5”) ID

Temperature 250 C (482 F)

Frequency 200 kHz

Equipment UM-10AB-UHF, induction heating system, equipped with a remote workhead containing two .33μF capacitors (for a total of .66 μF).

An induction heating coil designed and developed specifically for this application.

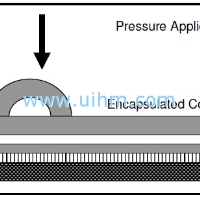

Process/Narrative A single-turn solenoid coil is placed around the assembled

beer keg and heated for 35 seconds as the keg is rotated.

Pressure is applied with a press on the top rim whilst the keg is

rotating, forming a seal between the aluminium mesh and the two halves of the beer keg.

Results/Benefits Induction heating provides:

. Quick, reliable, repeatable heat

. Localized, precision heat to the mesh area

Good

Bad

Related Content

Remove plastic coating from steel tubes by Induction Heating

induction bonding for glass frit sealing and metal alloy

induction melting steel or rare metal

induction bonding camera lens

Induction Bonding Solar Panel Shingles

Tilting Melting Platinum Furnace

Medium frequency vacuum melting furnace

Metal to Plastic by Induction Bonding

Newest Comment

No Comment

Post Comment