-

Keywords"at",total

1250 records

-

what is induction heat treatment

What is heat treatment eat treatment of metal is a method of manipulating the metal (in terms of its physical properties) to achieve the operational condition of the metal—both for machining and then for operation. Most metals can be made to be soft or ha…

-

what is annealing

What Is AnnealingAnnealing is a not just a simple process with just one effect and a single result. It is a complex technique that can be carried out in many different ways and at different steps in the manufacturing process to obtain different effects on …

-

induction silver brazing with induction heating

silver brazing with induction heatingInduction Silver brazing actually uses not pure silver, but instead a silver alloy containing nonferrous metal to bond two pieces of metal together. The process is typically used to join close-fitting parts that require…

-

induction silver soldering with induction heating

Silver soldering with induction heating A full treatise on silver soldering (otherwise known as hard soldering) would be an extensive document, and all I want to cover here is the basics. A serious job such as constructing a model locomotive boiler require…

-

induction heating brass mandrel die

Heating brass mandrel die Objective Water-cooled brass mandrel die, nylon LDPE catheter, “K” type thermocouple and temperature controller. Material materials, supplies involved in the application Temperature 400F (204C) Frequency 325kHz Equipment…

-

induction heating steel mandrel tip

Heating steel mandrel tip Objective Heat a water-cooled steel mandrel to 700F (371C) to form a high quality Teflon catheter tip.Material Teflon catheter tubing, mandrel assemblyTemperature 600-700F (315-371C)Frequency 376 kHzEquipment • Power of 10kW indu…

-

induction heating catheter tipping die

Heating Catheter Tipping Die Objective: To heat an aluminum catheter tipping die to above 2850F within 2 to 5 seconds for the forming of catheter material. Presently, heating is performed in 15 seconds with older induction equipment. The customer would lik…

-

induction heating fan blades for welding

Heating fan blades for welding Objective To uniformly heat jet engine turbine fan blades to 1800F (982.2C) within five minutes for a welding applicationMaterial Jet engine turbine fan blades with 2”(50.8mm) length tipTemperature 1800F (982.2C)Frequency 21…

-

induction soldering satellite antennas

Soldering satellite antennas Objective Soldering steel onto GPS body for phone antennaMaterial Thin copper foil 0.3mm (0.01 in) thick Ceramic body 12mm (0.47 in.) long x 7mm (0.28 in.) wideTemperature 200 C (392 F)Frequency 371 kHzProcess Time 5 secondsEqu…

-

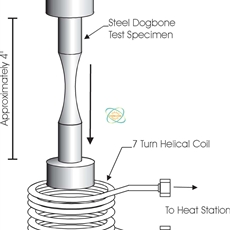

induction heating steel dogbone specimen

Heating Steel Dogbone Specimen Objective: To heat a magnetic steel dogbone specimen to 12000F as quickly as possible and sustained for tensile testing. Heating should take place using a helical coil placed square in relation to the long axis of the gage ar…