-

Keywords"Induction",total

2890 records

-

Induction brazing piston valve

Objective Brazing a steel piston valve assembly Material Steel piston valve 4.5” dia (11.43cm), tungsten carbide plate and braze Temperature 1350 F Frequency 91 kHz Equipment • Power of 90kW induction heating system, equipped with a remote workhead c…

-

Induction brazing brass faucet

Objective Brazing two joints on a brass bathroom faucet assembly Material Brass bathroom fittings 1” OD, brazing rings, flux Temperature 1148 F (620 C) Frequency 90 kHz Equipment • Power of 90kW induction heating system, equipped with a remote workhe…

-

Induction brazing manufacture needles

Objective Brazing stainless steel housings to stainless steel tube for gas assembly used in the manufacturing of needles Material 2 stainless steel housings .25” (6.35mm) dia, .675 (17.1mm) & .54” (13.7mm) in length, stainless steel tube .031” (.78…

-

Induction brazing copper pivot

Objective Brazing a copper pivot assembly Material Two copper uprights 2” (5cm) wide x 4” (10.2cm) high, copper base 3” (7.6cm) x 2” (5cm) and .5” (1.3mm) thick with 2 channels for the uprights to the slide into, braze shims and black flux Temperatu…

-

Induction brazing heat-sensing probe

Objective To heat a coil and a wire assembly to 1300F (704C) within 60 seconds for brazing. Material Platinum coil, steel wire, braze paste Temperature 1300F (704C) Frequency 307kHz Equipment Power of 6KW output, remote heat station containing one 1.2 …

-

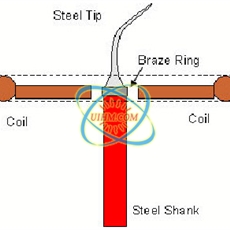

Induction brazing dental tools

Objective To heat a steel tip and shank assembly to 1300F (704C) within 3 seconds for brazing with induction heating instead of torch brazing. Material 0.1” (2.54mm) diameter steel tip & shank, 0.07” (1.78mm) diameter braze ring Temperature 1300F (…

-

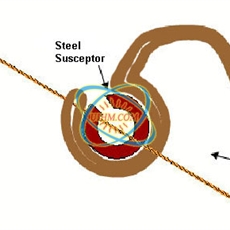

Induction brazing steel orthodontic parts

Objective To heat a batch of orthodontic parts to 1300F (704C) within 1 second in an inert atmosphere for brazing. Material Small stainless steel orthodontic parts, silver braze alloy, no flux, 3 1/ 8” (79.3mm) graphite susceptor disk with 1” (25.4) cen…

-

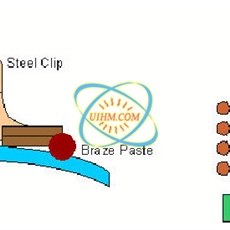

Induction bonding rubber to steel

Objective To bond rubber gaskets to the top and bottom of a steel gas tank assembly. Material Flat and round rubber gaskets, steel gas tank assembly Temperature 300 to 350F(148.9-176.7C) Frequency 183 kHz for the flat gasket; 231 kHz for the round gaske…

-

Induction coating aluminum

Objective To heat an aluminum molding shape in order to activate an adhesive coating prior to applying the vinyl Material Aluminum molding folded from a flat sheet measuring 2″ wide and 0.03″ thick. The final form measures 5/8″ by 1″ Temperature 500F…

-

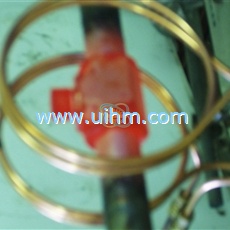

Induction brazing steel tube

Objective To braze a steel tube to a steel “T” fitting Material 1” (25.4mm) diameter steel tubing, steel fitting, braze slug and black flux Temperature 1400F (760C) Frequency 198 kHz Equipment • Power of 15kW induction heating system, equipped with…