-

Keywords"Induction",total

2890 records

-

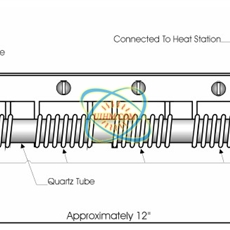

Induction annealing tungsten rods

Objective To heat customer-supplied rods of various diameters (0.14 inch to 0.49 inch) to 4170F (2300C) at 2-4 feet per minute Material Tungsten and Molybdenum; Tests are run in an atmosphere of Nitrogen or Hydrogen avoid oxidation of the materials. Temp…

-

Induction annealing titanium fasteners

Objective Heating a titanium fastener to 1100-1450F (593-788C) for an annealing process. Material 0.06” (1.5mm) high zone on a titanium fastener measuring 0.163-0.375” (4.14-9.52mm) in diameter and 0.5-3.0” (12.7-76.2mm) in length Temperature 1100-145…

-

Induction annealing brazing wire

Objective: Anneal a brazing wire for preform production. Material :Copper Nickel Silver 2774 Alloy rod 0.070″ (1.8mm) diameter. Temperature 650F(343.3C) Frequency 281 kHz Equipment • UM-06A-UHF induction heating system equipped with a remote workhead…

-

Induction annealing thread ring

Objective: To selectively and uniformly anneal two sections of a thread ring gage block from the hole to the outside surface from a hardness of Rc 59-61 to Rc 45. The gage blocks are made from O6 steel and range in size from 1″ to 8 1/2″ in …

-

principle of Induction heating (Induction heating principle)

induction-heatingINDUCTION HEATING was first noted when it was found that heat was produced in transformer and motor windings, as mentioned in the Chapter “Heat Treating of Metal” in this book. Accordingly, the Principle of induction heating was studied …

-

Induction bending and hot rolling

Induction Bending And Hot Rolling the 1620mmX40mm steel pipe in the West-East natural gas transmission project. Induction bending is also referred to as hot rolling, but there are some differences between the two processes. Induction bending is an ef…

-

Induction surface quenching works

Induction quenching is the process of quenching steel by heating it. It is done by an alternating magnetic field to a temperature above or within a specific transformation range. It is straight away followed by quenching. This procedure of quenching can be…

-

how Induction brazing works

Induction brazing is a process where two or more materials such as pipe are joined together with a molten space filler metal using an induction heating coil which delivers a very high temperature. The induction brazing process will involve temperature more…

-

Induction cooktops save energy, save money for you

An induction cooktop is a cooker which integrates vibrating magnetic energy to create heat. With induction, the heat generated used right into the cooking vessel instead of getting hot through flamable gas or electric coils. The heating vessel used for an …

-

Induction furnace cost effective and energy efficient

Raising the temperature of the items break down the complexity of the matter and simplifies the tedious process. Heating melts the hard structure of the substances and minutest of the details can be analyzed. There are many alluring shapes of hard metals.…