-

Keywords"in",total

3005 records

-

induction brazing steel orthodontic parts

Objective To heat a batch of orthodontic parts to 1300F (704C) within 1 second in an inert atmosphere for brazing. Material Small stainless steel orthodontic parts, silver braze alloy, no flux, 3 1/ 8” (79.3mm) graphite susceptor disk with 1” (25.4) cen…

-

induction bonding rubber to steel

Objective To bond rubber gaskets to the top and bottom of a steel gas tank assembly. Material Flat and round rubber gaskets, steel gas tank assembly Temperature 300 to 350F(148.9-176.7C) Frequency 183 kHz for the flat gasket; 231 kHz for the round gaske…

-

induction coating aluminum

Objective To heat an aluminum molding shape in order to activate an adhesive coating prior to applying the vinyl Material Aluminum molding folded from a flat sheet measuring 2″ wide and 0.03″ thick. The final form measures 5/8″ by 1″ Temperature 500F…

-

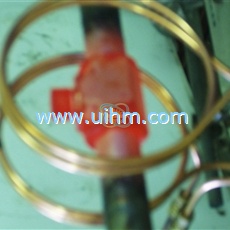

induction brazing steel tube

Objective To braze a steel tube to a steel “T” fitting Material 1” (25.4mm) diameter steel tubing, steel fitting, braze slug and black flux Temperature 1400F (760C) Frequency 198 kHz Equipment • Power of 15kW induction heating system, equipped with…

-

induction brazing stainless steel dental assembly

Objective To heat a steel dental assembly to 1400F (760C) for brazing Material Stainless steel plates 0.118” (3mm) square and 0.078” (2mm) high, stainless steel hook, mesh, two pieces of graphite 0.375”(9.5mm) square cross section, 4” (101.6mm) long a…

-

induction brazing aluminum tubing

Objective Heat aluminum for an automotive brazing application Material Aluminum tubing 0.50 (12.7mm) dia, an aluminum boss 1”(25.4mm) long, flux filled braze rings Temperature 1200 F (649 C) Frequency 270 kHz Equipment •Power of 10kW induction heatin…

-

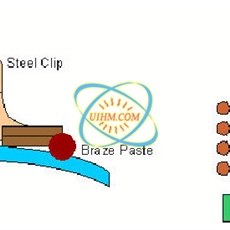

induction brazing steel mold

Objective Heating steel golf ball mold to brazing dimple insert Material Golf ball mold 2” in diameter, braze flux paste, dimple insert Temperature 1400 F (760 C) Frequency 206 kHz Equipment • Power of 20 kW induction heating system, equipped with a …

-

induction brazing copper joints

Objective Brazing a joint between a copper lug and nickel plated copper pins on a pressurized heater connector. Material 1.5” (38.1mm) dia heater connector in a ceramic insulator with L shaped copper lugs and nickel plated copper pins, silver solder and …

-

induction brazing stainless steel joint

Objective Braze an end plug on a stainless steel joint of the car grill before powder coating application Material Stainless steel car grill 0.5” x 0.19” (12.7mm x 4.8mm), end plugs and braze ring Temperature 1350 F (732C) Frequency 267 kHz Equipment…

-

induction brazing stainless steel hose to copper elbow

Objective Braze a stainless steel braided hose to copper elbows for a braided hose assembly. Material Stainless steel braided hose 3/8” (9.5mm) OD, copper elbow 1/4” (6.3mm) OD, braze preform rings and black flux Temperature 1400 F (760 C) Frequency 2…